Current position:

Home >

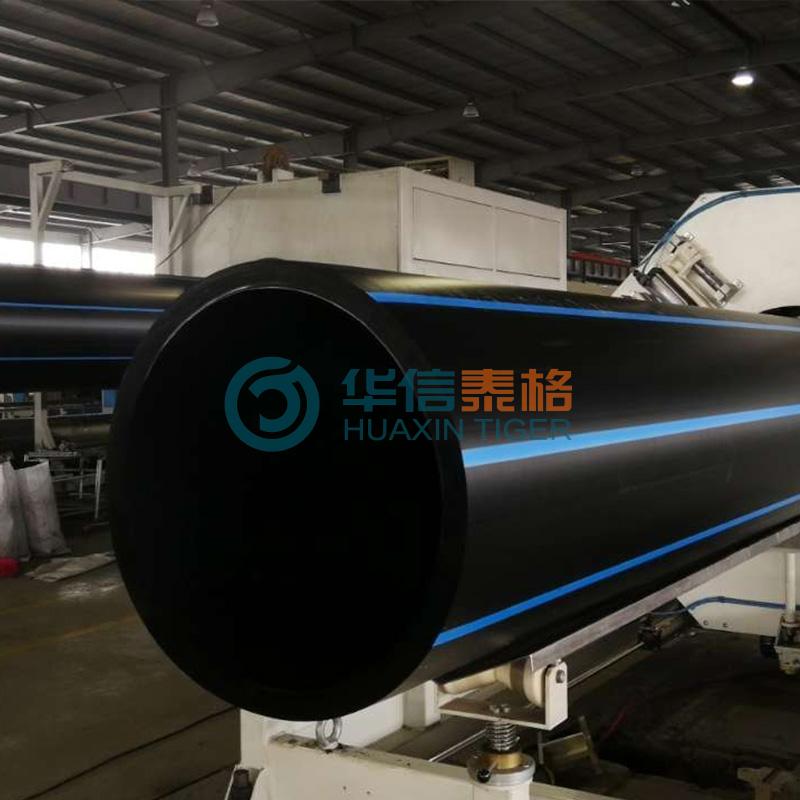

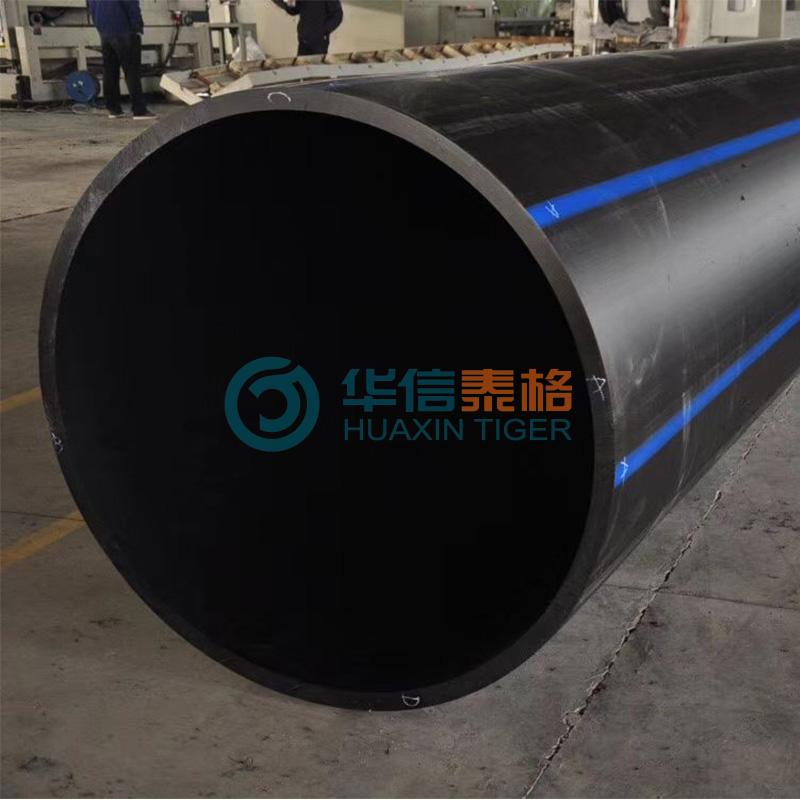

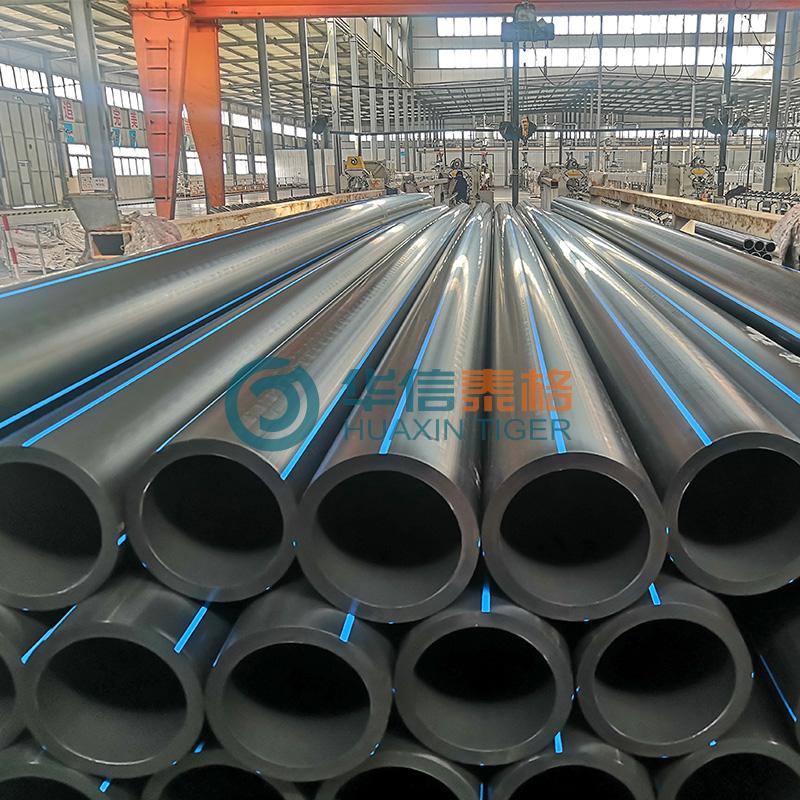

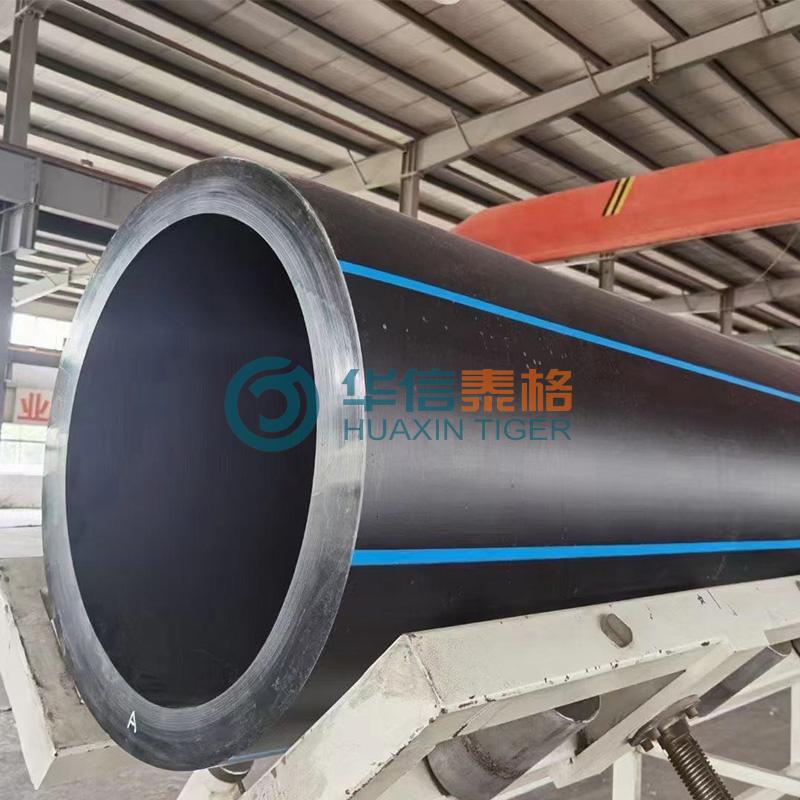

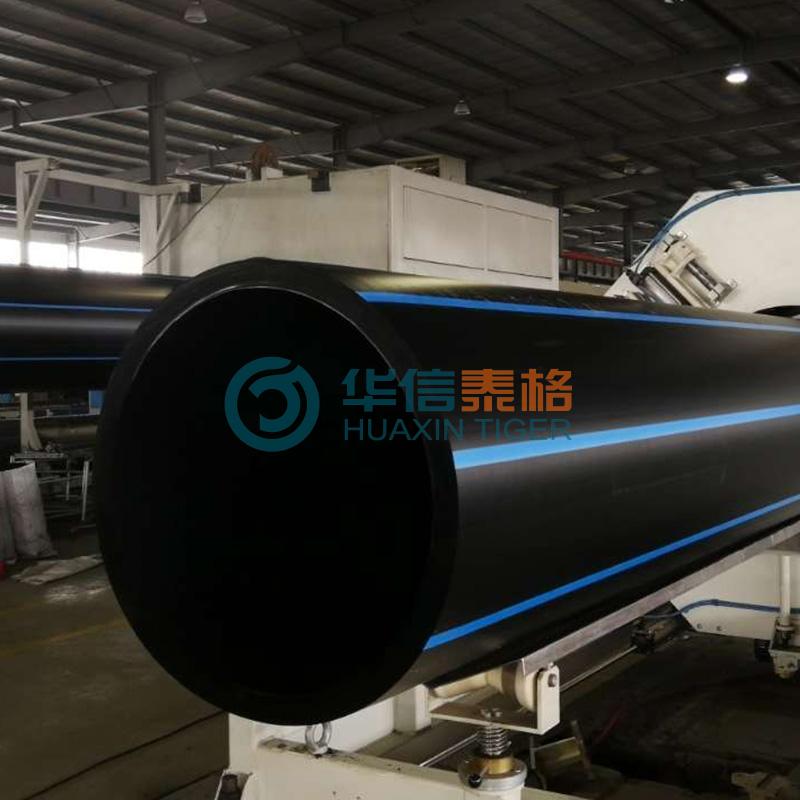

PE water supply pipes

QR code

Characteristic

1. Reliable connectionThe polyethylene pipeline system is connected by electric heating fusion, and the strength of the joints is higher than the strength of the pipeline body; Polyethylene pipelines are connected to other pipelines using flanges, which is convenient and fast.2. Excellent low-temperature impact resistanceThe low-temperature embrittlement temperature of polyethylene is extremely low, and it can be safely used within the temperature range of -60 ℃ -+60 ℃. During winter construction, due to the good impact resistance of the material, pipe embrittlement will not occur.3. Excellent resistance to stress crackingHDPE has low notch sensitivity, high shear strength, and excellent scratch resistance, making it highly resistant to environmental stress cracking.4. Excellent chemical corrosion resistanceHDPE pipes can withstand corrosion from various chemical media, and the chemicals present in the soil will not have any degradation effect on the pipes.5. Aging resistance and long service lifePolyethylene pipes containing 2-2.5% uniformly distributed carbon black can be stored outdoors or used for 50 years without being damaged by ultraviolet radiation.6. Good wear resistanceThe comparative test of wear resistance between HDPE pipes and steel pipes shows that the wear resistance of HDPE pipes is four times that of steel pipes. In the field of mud transportation, HDPE pipes have better wear resistance compared to steel pipes, which means that HDPE pipes have longer service life and better economy.7. Good flexibilityThe flexibility of HDPE pipes makes them easy to bend, and in engineering, they can bypass obstacles by changing the direction of the pipes. In many cases, the flexibility of pipes can reduce the amount of pipe fittings and reduce installation costs.8. Low water flow resistanceHDPE pipes have a smooth inner surface with a Manning coefficient of 0.009. The smooth surface and non adhesive properties ensure that HDPE pipes have higher conveying capacity than traditional pipes. At the same time, it also reduces the pressure loss and water transmission energy consumption of the pipeline.9. Convenient handlingHDPE pipes are lighter than concrete pipes, galvanized pipes, and steel pipes, making them easier to handle and install, with lower labor and equipment requirements, which means a significant reduction in the installation cost of the project.10. Excellent diversity of construction methodsHDPE pipelines have various construction techniques. In addition to traditional excavation methods, they can also be constructed using various new non excavation techniques such as pipe jacking, directional drilling, lining, and cracking. This is the only choice for some places where excavation is not allowed, so the application field of HDPE pipelines is more extensive.